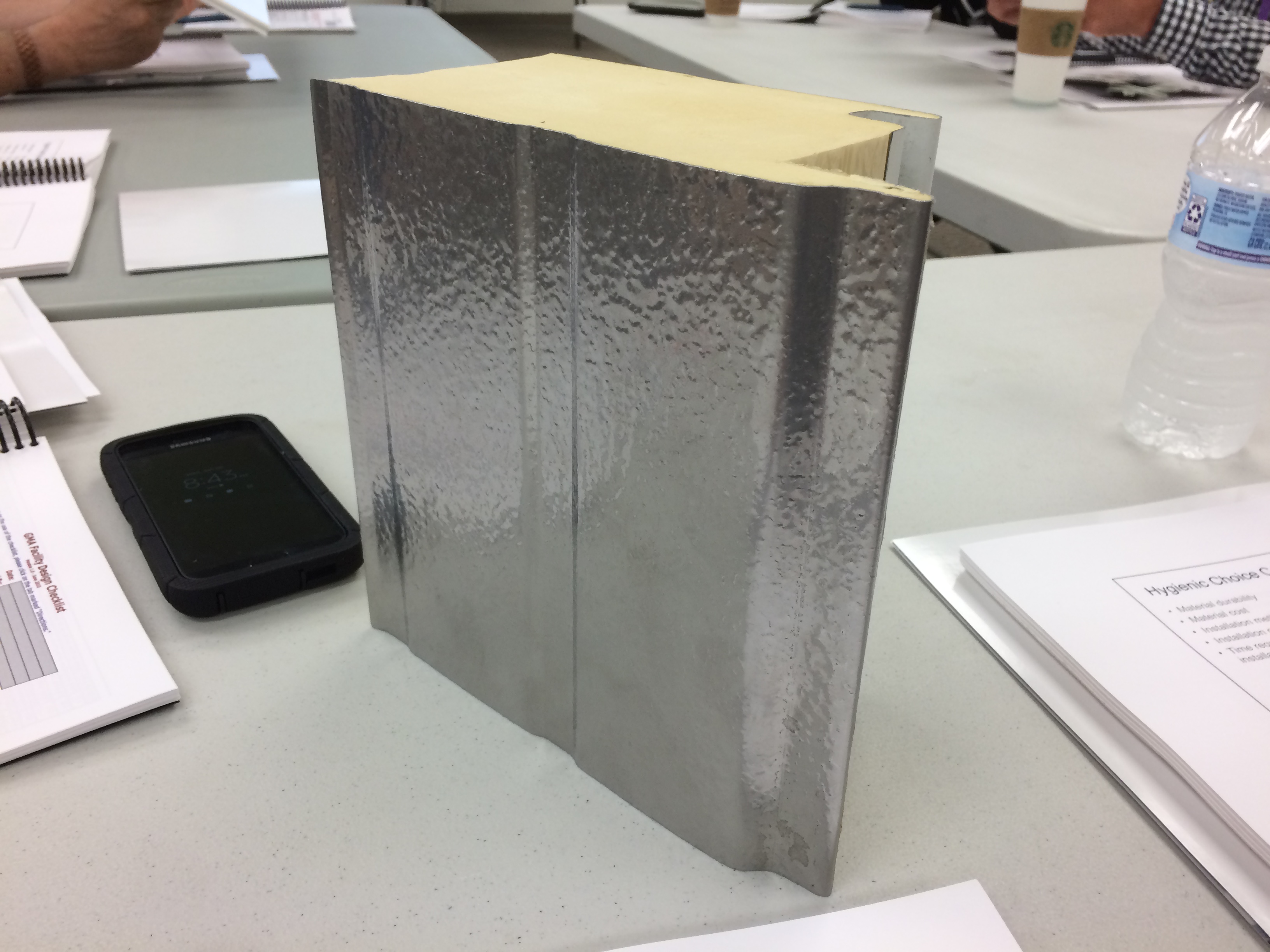

The insulation material provides the walk in with resistance to heat flow which allows the walk in to be refrigerated and hold cold temperatures.

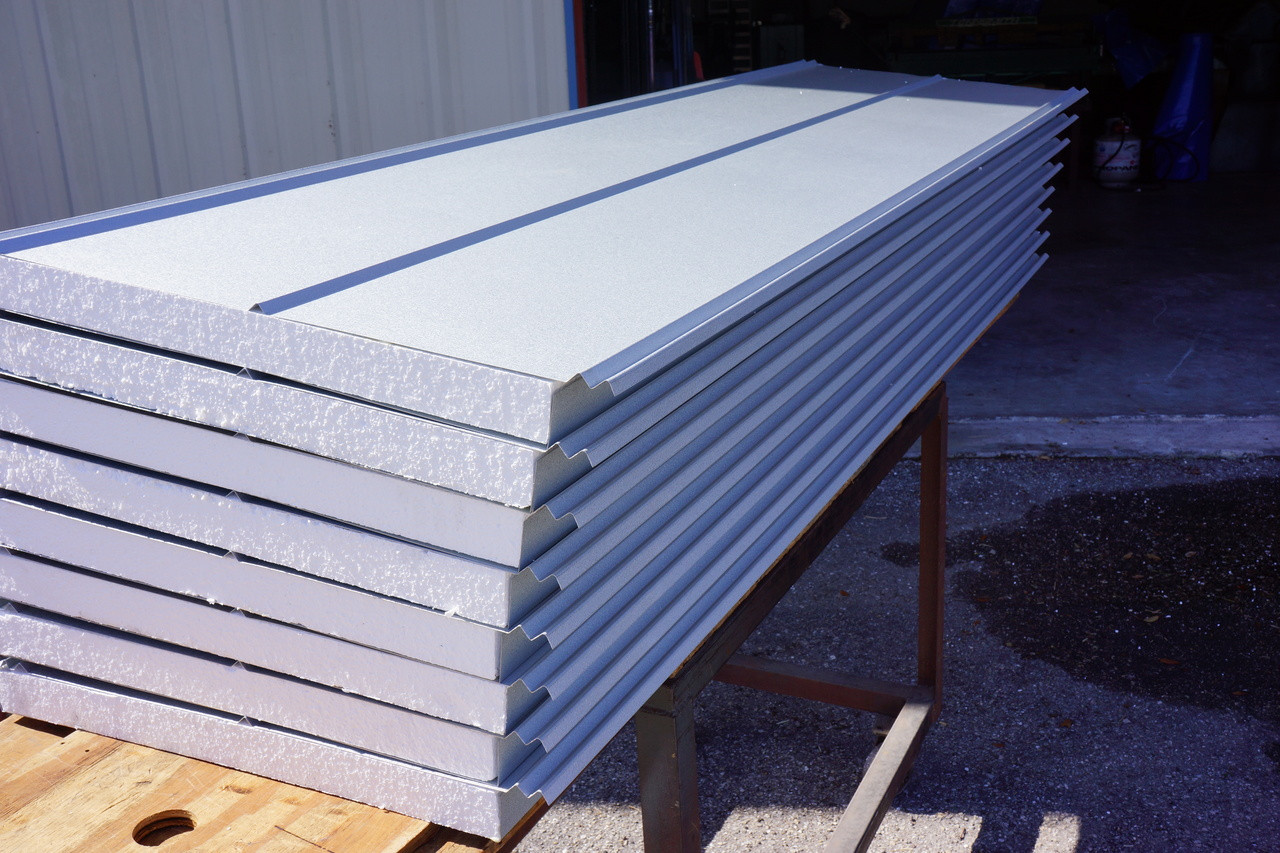

Walk in cooler insulation panels.

A very good cooler can be built using dimensional lumber and standard framing.

At this point the walk in cooler is assembled.

Protect framing and insulation with smooth cleanable materials and vapor barrier to prevent moisture and condensation inside the walls.

Types of insulation in the walk in cooler and freezer business there are two common types of plastic foam insulation polyurethane and extruded polystyrene.

If you need a few panels or a full truckload we can load you up with as many as you need at blowout prices.

Build your own walk in cooler or freezer for your brewery convenience store or restaurant and save thousands.

Concrete floors should be insulated if your target room temperature is below 37 f.

The lower the k factor the better the insulation performance.

Our insulated refrigeration panels snap together easily and make great walls for indoor gardening and hydroponic cultivation.

Some common applications are.

However it is not ready to be used.

Do not use fiberglass insulation it is not a recommended choice for walk in coolers.

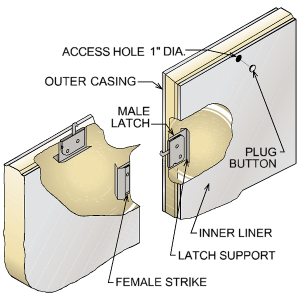

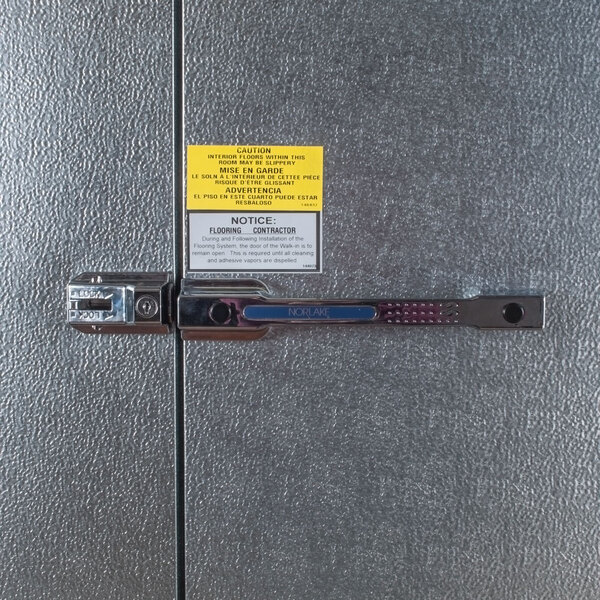

Silicone is used to seal the holes cut through the insulation panels maintaining a water tight seal.

When it comes to refrigeration panels the r value is typically provided as the k factor which is the thermal conductivity for a unit thickness of material.

Walk in cooler or freezer.

Contact our sales team at 877 220 8882 or locally at 216 426 8882 to order your panels today.

Try to achieve r 25 value using rigid foam sheets or spray foam.

Our panels are manufactured exclusively for american wholesale and meet all local state and federal codes.

New cooler and freezer insulated panels american wholesale is now offering unbeatable wholesale prices on our american series insulated panels.

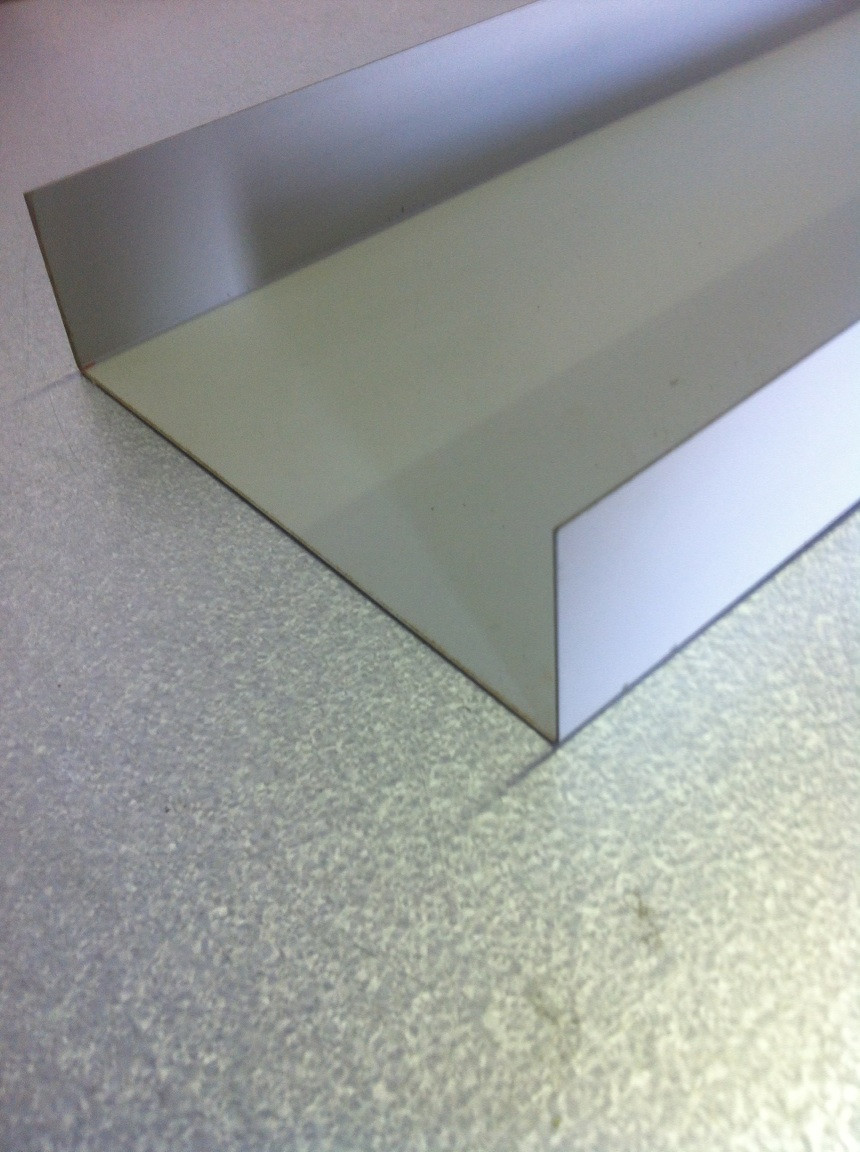

Coolstructures insulated panels are a snap to install using a simple tongue and groove design than reduces thermal bridging heat loss so prevalent in more complex designs.

Wall panels simply slide into place and are easily secured to the building s steel superstructure.

Industry standard r value for walk in coolers is r 25.

We keep many sizes of cooler and freezer insulation panels in stock all ready to ship.

The evaporator needs to be plumbed and attached to the external condenser.

We can include and ship all the installation trim necessary to put your cooler freezer units or sealed modular grow rooms together.